- +86 (0) 20-86655668

- info@gionar.com

English

English

May 22 , 2025

Banana leather is a kind of plant leather made from the waste of banana crops and has significant environmental protection advantages. At present, Banana leather has been widely used in the fashion, furniture, automotive and packaging industries, demonstrating broad commercial value and application prospects, and providing a new option for the sustainable fashion and environmental protection industries. This article will elaborate on how banana leather is manufactured and what advantages and disadvantages it has.

Banana leather (also known as banana fiber leather or banana silk leather) is an innovative and environmentally friendly material extracted from the banana plant, made from the stems and pseudostems of the banana plant – a by-product of banana cultivation. It is a sustainable alternative to traditional animal leather and synthetic leather, offering a unique combination of environmental benefits and practical applications, reducing reliance on animal products and synthetic leather extracted from fossil fuels.

Yes, banana peels can be reused in leather production and care, but their role varies between practical leather substitutes and supplementary uses.

The advantages of making leather from banana peels include the use of waste products. Flexible texture. It can be processed through drying, pressing and coating to make its appearance and feel like leather.

Yes. Banana leaves are more suitable materials for making leather than banana peels, and they are better than banana peels in terms of durability and structure. Banana peels are usually not as ideal as banana fibers (from pseudostems or leaves). Banana fiber leather is stronger and more suitable for use in manufacturing materials, so banana fibers are very suitable for making leather materials.

How is banana leather made? The process of making “banana fruit leather” (a leather-like material made from banana waste) usually involves extracting fibers from banana plant waste rather than directly processing the banana fruit itself. However, if one intends to produce a material with leather-like properties from banana waste (such as pseudostems or banana peels), the general method is as follows:

Using banana pseudostems, peels or other plant waste, these materials are rich in cellulose fibers and are the main raw materials for banana leather.

Fibers are separated from plant materials by mechanical or chemical methods, and fibers are extracted from pseudostems. This may involve crushing, soaking or using enzymes to break down plant tissues and release fibers.

Clean and soften the extracted fibers. Sometimes they may need to be mixed with natural adhesives (such as natural gum or resin) to enhance their strength, durability and flexibility.

The processed fibers are compressed into sheets or multiple layers, which can be achieved through molds or pressing techniques to ensure uniform thickness. Then, after processing, it is made similar to the texture and appearance of traditional leather.

Color the materials with natural dyes or pigments. Apply a protective layer (such as natural wax or resin) to enhance durability and water resistance.

Dry naturally or use low-heat methods to avoid damaging the fibers. Once dry, the material can be cut, sewn or molded into the desired shape.

The strength and flexibility of the final material depend on the quality of the extracted fibers.

Natural materials may not be as durable as synthetic leather or animal leather and require additional treatment to extend their service life.

Large-scale production of banana leather requires efficient fiber extraction and processing methods.

Banana leather (mainly made from banana stems rather than banana peels) is an emerging eco-friendly alternative to leather.

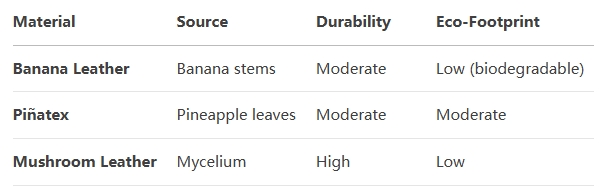

Made from agricultural waste (banana stems discarded after harvest). If left untreated, it is biodegradable (unlike PU/PVC artificial leather). It requires less water than the production of animal leather.

Animal-free products attract ethical consumers. Be in line with the slow fashion movement.

Softer and more flexible than hard PU leather. Ideal bags, wallets and accessories.

Increase the value of banana cultivation by monetizing waste.

Natural textures and texture variations, the natural feel adds uniqueness to each piece of work. It can be processed through drying, dyeing, pressing and coating to make its appearance and feel like leather.

It is naturally soft and can be shaped, making it a very good foundation.

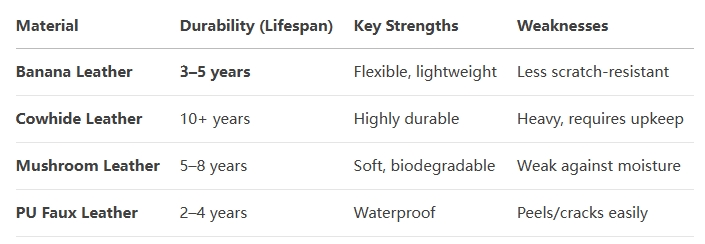

It lasts for 3 to 5 years (compared to full-grain leather that lasts for over 10 years), and is not as durable as animal leather. It is prone to scratches and tears under excessive use.

Absorb moisture unless treated with wax or coating. It is not suitable for rainy climates or frequent cleaning. If not properly dried and sealed, it is prone to rot or mold.

Due to its small production scale, it is more expensive than PU leather produced in large quantities.

It is more difficult to purchase than cowhide and PU leather. Most producers are in India, the Philippines and Uganda.

Plant hair conditioners (such as coconut oil) are needed to prevent dryness. Avoid prolonged exposure to sunlight to prevent fading.

It is most suitable for light use, such as fashion accessories or art projects, but not for items that require high tensile strength or long-term wear and tear.

Consumers may not yet be aware that banana peels are a viable alternative, and some may still prefer the look and feel of traditional leather.

Banana leather is a promising sustainable material, but they are still evolving. It is an ideal choice for eco-friendly brands and lightweight products, although its durability still cannot be compared with that of animal leather.

Bag: Handbag, tote bag.

Shoes: sandals, upper of sports shoes.

Accessories: Wallet, watch strap.

Fashion: Clothing, shoes, bags and accessories.

Furniture: Interior decoration and decorative elements.

Cars: Interior decoration and seats.

Consumer goods: wallets, belts and other small leather goods.

Banana leather lasts for 3 to 5 years. The durability of banana leather depends on their production methods and usage, but they usually fall between traditional leather and other plant-based alternatives. Banana leather is durable enough for fashion items and accessories, but it is not a perfect alternative for heavy items such as work boots or furniture.

Scratch resistance: Medium (lower than cowhide but better than PU).

Water resistance: Wax treatment is required; Avoid prolonged soaking. After treatment, it can be waterproof and enhance durability.

Flexibility: Maintain a good shape, but may harden over time.

Good tensile strength: Banana fiber is naturally very strong, which makes the base material quite solid.

Flexible and lightweight: With excellent flexibility, it is an ideal choice for fashionable applications such as handbags or shoes.

Adhesive: Plant-based latex or chitosan can enhance strength.

Coating: Beeswax or natural oils enhance water resistance.

Usage: Most suitable for low-friction items (handbags, wallets), rather than heavy bags.

Maintain with vegetable oil (such as coconut oil) once a month.

Avoid direct sunlight/dampness.

Reinforce the force-bearing points (for example, bag handles with fabric backing).

Banana peels made of high-quality fibers, strong adhesives and protective coatings can be very durable. It is most suitable for products that prioritize sustainability and acceptable moderate durability (for example, daily accessories). For high-stress applications (for example, heavy footwear, outdoor equipment), it may require additional reinforcement or mixed materials.

Yes. Banana leather is a good choice for certain types of bags, especially fashionable or casual ones, but its suitability depends on your priorities (sustainability and durability), as it has unique advantages and some limitations.

Banana leather is light and flexible, with a natural and simple appearance, and can be finished in a creative way like traditional leather. It can be dyed, embossed or laminated to enhance durability and visual appeal. Banana leather is excellent for brands and consumers seeking sustainable vegetarian alternatives.

If you want to customize banana leather bags, you can choose Gionar, which allows you to design bags that suits your brand style and values.

Gionar can offer customized services for banana leather bags, including materials, colors, hardware and logos, etc. Gionar has 19+ years of experience in custom leather goods manufacturing and can be a reliable partner for your banana leather bags brand.

Related leather bags customized services:

material Genuine Leather Closure Type Open Lining suede…

Mobile Website

Inquires Whatsapp