- +86 (0) 20-86655668

- info@gionar.com

English

English

August 13 , 2025

American leather bag manufacturers are renowned for their localized production and high-end customization, as well as their high quality, innovative design and customized services. They are mainly concentrated in places like New York and California. The types of products manufactured cover various categories such as backpacks, tote bag, briefcases, and eco-friendly bags.

Many American bag factories support small-batch customization. They are equipped with advanced production facilities, attach great importance to environmental protection and sustainable materials, and are suitable for bag brand owners and corporate gift customization.

|

Top 10 best leather tote bag manufacturers in USA |

|||

| Manufacturer | Established | Customized | MOQ |

| Softline | 2014 | bags, watch straps | Flexible |

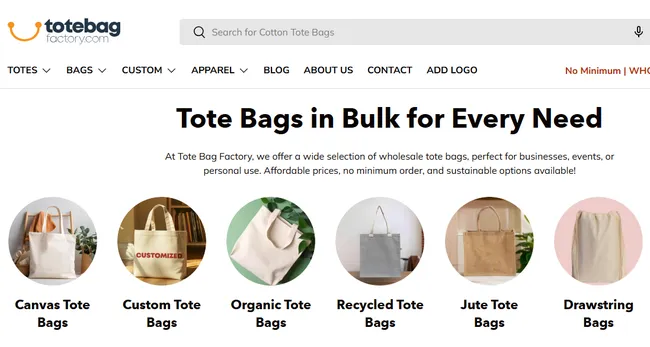

| Totebagfactory | Unknown | Canvas Tote Bags, Drawstring Bags – Backpacks, Wine Bags, Laundry Bags | Flexible |

| gfgbagmanufacturer | Unknown | handbags, backpacks | 100-1000 |

| thecustombag | Unknown | Tote bags, backpacks, crossbody bags, tablet bags, luggage bags, small bags, briefcases | 100-250 |

| Oasis Bags | 2004 | luggage, travel bags, backpacks, business briefcases, casual tote bags | Flexible |

| bagmanufacturerusa | Unknown | schoolbags, briefcases, women’s bags | 500 |

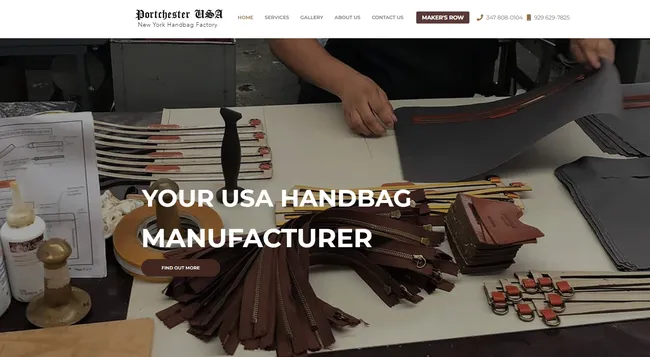

| portchester | 1984 | handbags | Flexible |

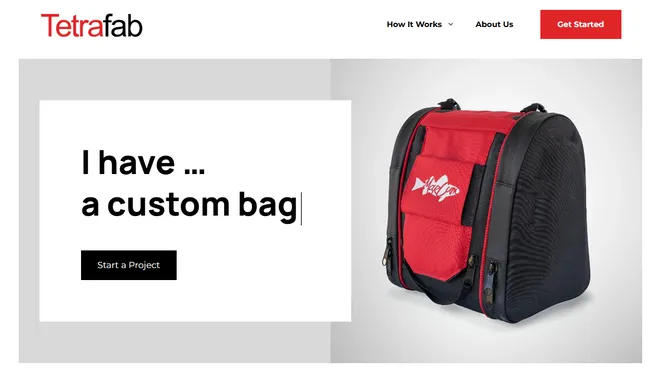

| Tetrafab | Unknown | Custom Backpacks, Portable Electronic Cases, Medical Cases | Flexible |

| LBU | 1990 | Bags, packaging, aprons, pillows, backpacks, duffle bags | Flexible |

| landes | 1971 | totes, duffels | Flexible |

This article will introduce the top ten bag manufacturers in the United States. If you are looking for a leather bag manufacturer, this article is worth reading carefully. Of course, in addition to considering leather bag manufacturers in the USA, you can also consider leather tote bag manufacturers in China, such as Gionar.

As an industry leader in the field of soft commodity manufacturing, Softline Brand Partners, with its global production layout and vertically integrated supply chain system, provides one-stop manufacturing solutions from design to delivery for all kinds of enterprises. The company was established in 2014 and has now developed into a comprehensive manufacturer covering the production of multiple categories such as leather goods, household items, and industrial accessories. Its clients range from start-ups to Fortune 500 brands.

Factories have been established in the United States, China, Vietnam, India and Mexico to achieve flexible capacity allocation and meet the cost and timeliness requirements of different markets.

The domestic factories in the United States are dedicated to providing rapid response services for “Made in the USA” brands, shortening the supply chain cycle.

Their cooperative clients include well-known brands such as Love Your Melon (fashion accessories), Allen Edmonds (high-end footwear), and Timex (wristwatches).

They once helped clients achieve a large-scale growth in monthly sales from 5,000 units to over 1 million units, with the average cycle shortened to within 18 months.

Softline Brand Partners has always adhered to the principle of “quality first and reliable delivery”, and is committed to becoming the most trusted manufacturing partner for customers.

Cooperation process: Customer puts forward requirements → Design simulation and material selection → sample production → mass production and global logistics distribution. Whether it’s niche customization or large-scale orders, they can provide customized solutions.

As a leading luggage wholesaler on the west coast of the United States, Totebagfactory (affiliated with Smart-K LLC) has been ASI certified since 2012 and is committed to providing luggage products with both quality and price advantages for small and medium-sized enterprises, retailers and individual consumers. The company has established an efficient supply chain system through a business model of “direct procurement + nationwide warehousing in the United States”, thus forming a unique competitive edge in the highly competitive market.

By establishing direct cooperative relationships with manufacturers in China, Southeast Asia and other regions, the costs of intermediate links can be eliminated, reducing the wholesale prices of products such as canvas tote bags and drawstring bags by 20-30%. This “cost transparency” strategy benefits customers, especially small businesses and start-up brands.

With the Garden Grove operation center in California as the core, distribution warehouses have been established in eight key cities including Atlanta and Dallas, achieving delivery within 48 hours in 90% of the United States and significantly reducing the inventory pressure on customers.

Although positioned in the affordable market, all products have passed the ASI certification standard testing, with particular emphasis on practical indicators such as the thickness of the cotton canvas (10-16oz) and the stitch density (8-10 stitches per inch), balancing cost performance and durability.

Totebagfactory discontinues the short-term profit-driven mindset and continuously provides entrepreneurial friendly supply chain support for small and medium-sized customers through large-scale procurement and refined operation. Its business practice has proved that the low-price strategy and quality assurance are not contradictory – since 2020, the customer repurchase rate has remained stable at over 65%, confirming the market’s recognition of its “fair trade” concept.

As a bag manufacturing expert with 18 years of industry experience, GFG is committed to providing one-stop customized services from design to delivery for brand owners, designers and institutional clients. The company takes its vertically integrated supply chain system and flexible production mode as its core competitiveness, and its service scope covers multiple fields such as promotional gifts, tactical equipment, fashion handbags and commercial packaging.

They have built their own cross-border logistics team to handle complex links including import customs clearance and multi-warehouse distribution. They can achieve delivery within 72 hours in North America.

Customer satisfaction reached 98% (based on over 2,000 five-star reviews from Google). Typical cases include:

GFG abandons the passive order-taking model of traditional contract manufacturers and helps customers avoid inventory risks through pre-design consultation and data-driven production management. Its core advantage lies in:

For enterprises pursuing brand differentiation and supply chain efficiency, GFG’s “light-asset collaboration” model (where customers only need to provide creativity and the rest of the process is handled by GFG) is becoming the preferred solution in emerging markets.

Custom Bag Company is a manufacturing service provider specializing in brand Custom bags, committed to providing high-quality and personalized wholesale promotional bags for all kinds of enterprises and individual customers. The company ensures that products are delivered on time and within budget by directly connecting customers with manufacturers, while maintaining a flexible production model to meet demands of different scales.

They offer a full range of bags including tote bags, backpacks, drawstrap bags, crossbody bags, tablet bags, luggage bags, small bags, briefcases, etc., suitable for various scenarios such as promotional activities, corporate gifts, and retail displays.

Supports special functional designs, such as waterproof coating, anti-theft structure, foldable storage, etc.

The company’s service targets are extensive, including:

Typical cases include customizing 5,000 eco-friendly tote bags for a technology company (delivered within 4 weeks), and assisting a fashion brand in developing limited edition crossbody bags (providing full support from design to mass production).

For enterprises that hope to enhance brand influence or optimize the efficiency of purchasing promotional items, custom bag companies, with their low minimum order threshold, quick response and all-round customization services, have become reliable partners.

The Bag Company (with its brand Oasis Bags) has developed into one of the major luggage suppliers in the markets of the United States, Canada, Australia and the United Arab Emirates since its establishment in 2004. The company takes high-quality inventory products and customized services as its core competitiveness, providing global customers with luggage solutions that are functional, durable and fashionable in design.

The product is made of high-density nylon, wear-resistant polyester fiber and top-quality leather, etc., to ensure its durability.

Surface treatment processes (such as waterproof coating and matte embossing) enhance both practicality and aesthetics.

They implement strict factory inspection procedures, including load-bearing tests and seam strength inspections, etc. The defective product rate is lower than the industry average.

Supports small-batch orders starting from 500 pieces, with a production cycle of 4 to 6 weeks (depending on complexity).

They offer design consultation and sample-making services to help brand owners achieve product differentiation.

For enterprises seeking a stable supply chain, rapid delivery or brand customization, The Bag Company (Oasis Bags) has become a trusted partner with its global layout and flexible business model.

Bag Manufacturer USA is one of the large-scale Bag manufacturers in North America. With its diversified product matrix and global production capacity, Bag Manufacturer USA has become a core supply chain partner for commercial retailers, brand owners and distributors. The company continuously provides global customers with bag solutions that conform to contemporary consumption trends through a vertically integrated manufacturing system and flexible marketing strategies.

With the manufacturing base in the United States as the core, cooperative factories are simultaneously established in Asia, South America and other regions to form cross-regional production capacity synergy, supporting rapid response and cost optimization.

Ensure the consistency of product quality in different production areas through standardized production processes (ISO 9001 certification).

With over 5,000 ready-made design libraries, covering all categories such as children’s schoolbags, business briefcases, and fashionable women’s bags, it supports direct selection or light customization (LOGO, color matching, etc.).

Their professional design team adds over 300 original designs each year, keeping pace with the latest trends in fashion capitals like New York and Milan.

Customer groups: Main service areas include chain retailers, e-commerce platforms and brand distributors. Typical cases include:

Gradually increase the proportion of recycled polyester fiber (rPET) and organic cotton used in the product line to 30%.

Reduce the carbon footprint per unit product by optimizing the logistics network (regional warehouses + consolidated sea freight).

For commercial customers seeking stable supply sources, trendy designs or large-scale customization, the competitiveness of Bag Manufacturer USA is reflected in:

Since its establishment in 1984, Portchester USA has always been rooted in Long Island City, New York, providing full-process services from design to production for the fashion industry. The founder, Kulwant Chouhan (respectfully known as “KC” in the industry), with his professional design education background (graduated from the CAD/CAM program at Matatake Community College in Connecticut in 1983) and acute industry insight, transformed this small studio, which was originally located near the Fashion Institute of Technology in Manhattan, Develop into a professional manufacturer serving first-line brands such as Kate Spade and Oscar de la Renta.

Portchester USA, with its “Made in the USA” label and the geographical advantage of the New York fashion circle, occupies a unique position in the high-end handbag market:

For brands that pursue the quality and design tone of “Made in the USA”, Portchester USA remains a rare professional partner in the East Coast region. With 41 years of industry accumulation, it has a unique advantage in understanding fashion trends and controlling product quality.

Tetrafab is dedicated to providing high-quality custom-sewn products for brand customers. The company takes establishing long-term cooperative relationships as its core concept and is committed to helping customers enhance brand value through innovative design and precise manufacturing.

Tetrafab positions itself as a growth partner for its customers rather than a simple supplier. This philosophy has enabled it to establish an outstanding reputation in the field of custom luggage manufacturing. The company’s unwavering pursuit of quality and all-round service support make it an ideal choice for enterprises seeking high-end customized solutions.

Since its establishment in 1990, LBU (formerly known as LBU Manufacturing) has accumulated over 30 years of professional experience in the field of cutting and sewing products. The company’s headquarters is located in Patterson, New Jersey, with a 40,000-square-foot self-owned production base. The current CEO, Jordan Scaduto (the stepson of the founder Jeff Mayer), leads the enterprise to continuously promote product innovation and quality improvement.

LBU maintains a leading position in the industry with its unique business model:

According to industry analysis, the core competitiveness of LBU lies in its unique ability to combine traditional sewing techniques with modern marketing demands. Under the leadership of Jordan Scaduto, the company is actively expanding into emerging fields such as intelligent customization and sustainable production, and continuously consolidating its leading position in the promotional products manufacturing industry in the United States.

Since its establishment in 1971, Landes USA has been dedicated to providing fabric solutions that combine practical functionality with fashionable design, serving the fields of commercial promotions, industrial equipment, and professional toolkits. Relying on a professional design and development team, the company provides customers with full-process customized services from concept to finished product. The products cover a wide range of categories such as promotional handbags, industrial special bags and sales tool kits.

It is made of materials such as canvas, polyester and nylon, and supports full-color printing or screen printing processes to meet the needs of brand promotion.

Produced domestically in the United States, ensuring rapid delivery and controllable quality.

Designed specifically for heavy industry workers such as oil workers, it enhances durability with high-density vinyl and reinforced sewing techniques, making it suitable for harsh working environments.

Customized solutions, optimizing product display and carrying functions, help sales personnel efficiently complete customer demonstrations.

LandesUSA takes functional design and American manufacturing as its core competitiveness and has long served customer groups that need to balance practicality and brand image. Its products are widely used in industries such as energy, retail, and exhibitions, and it continuously meets diverse demands through material innovations (such as lightweight nylon and waterproof coatings).

The best bag manufacturers in the United States each have their own advantages. Typical enterprises such as Portchester USA (New York) focus on handcrafting, while Tetrafab (California) is renowned for military-grade quality control, meeting the differentiated demands of brands. If you are looking for a leather bag manufacturer with better cost performance, you can consider leather bag manufacturing factories in China.

Customize handbags in collaboration with world-class handbag manufacturers.

Previous :

Next :

Where are Coach bags made? China, Vietnam, Philippines or USA?material Genuine Leather Closure Type Open Lining suede…

Mobile Website

Inquires Whatsapp