- +86 (0) 20-86655668

- info@gionar.com

English

English

July 8 , 2025

Florence, as the core of Italian leather goods manufacturing, holds an important position in the global high-end leather bag market with its over 600-year-old craftsmanship tradition and complete industrial chain. The leather bag manufacturing in Florence is a perfect blend of traditional craftsmanship and modern design, becoming a synonym for high-quality leather goods.

This article will introduce leather bag manufacturers in Florence, Italy. It will be helpful for friends who are looking for high-quality leather manufacturers.

As the cradle of the European leather industry, Florence has remained at the core of global high-end leather bag manufacturing with a 600-year-old tradition of leather goods. Its core advantage lies in:

Craftsmanship Inheritance: Gathering many century-old handicraft workshops, it retains ancient techniques such as hand-cutting leather and vegetable-tanning dyeing. Each bag requires 15 to 20 manual procedures.

Top-quality raw materials: Adjacent to the Tuscan vegetable-tanned leather production area, it features top-notch tanning plants.

Luxury brand cooperation: OEM for Gucci, Ferragamo, etc., and incubate local high-end brands such as Piero Tucci and The Bridge at the same time.

Industrial ecosystem: It possesses a complete industrial chain from tanning, processing to design.

Today, Florence is competing against fast fashion with “slow manufacturing”, producing over a million high-end handbags annually, accounting for 35% of Italy’s leather goods exports. Its “Made in Florence” label has become a guarantee of quality and collection value.

The 10 best leather bag manufacturers in Florence, Italy |

||

| Manufacturers | Established | Customized |

| Jenny & Co | Unknown | All kinds of leather goods |

| florenceleatherfactory | The early 1980s | Handbags, tote bags, suitcases and belts |

| florenceleather | Unknown | Single-shoulder bags, handbags, clutch bags, backpacks |

| niccolibags | 1972 | All kinds of bags |

| loipell | 1993 | All kinds of handbags |

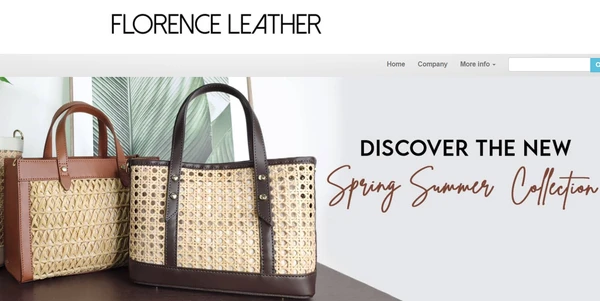

| Florence Leather | Unknown | Tote bags, clutch bags, wallets, belts |

| Florence Leather | Unknown | Tote bags, clutch bags, wallets, belts |

| Fratelli Peroni | Unknown | All kinds of leather bags |

| EFFEBI | 1950 | Men’s handbags, women’s handbags |

| G.A.S. Group | 2002 | Handbags, backpacks |

| Pierotucci | 1972 | leather bag, wallet, belt |

Jenny & Co is a leather bag manufacturer located in Florence, Italy, dedicated to combining traditional craftsmanship with industrial efficiency. The manufacturing process of Jenny & Co

Jenny & Co is dedicated to creating unique leather bags using 100% Italian leather.

Jenny & Co works closely with customers and uses professional knowledge to select the highest quality materials and hardware. Jenny & Co jointly determine the most suitable process flow to achieve the quality and cost targets required for the final product.

The team of Jenny & Co will guide you throughout the entire process from design to craftsmanship. Starting from your sketches, Jenny & Co develops CAD models and patterns, creates prototypes, and finally completes the samples, turning your vision into reality.

After the order is confirmed, Jenny & Co will manage the entire production process, including the procurement of raw materials and accessories, cutting, preparation, intermediate processing and assembly. Every step is strictly monitored to ensure the highest quality standards are met.

Jenny & Co integrates customers’ specific logistics demands into its internal processes to meet requirements such as RFID tags, barcodes or special packaging. In addition, Jenny & Co also provides global distribution services for B2B and B2C channels through its partners. They can provide value-added services according to customer needs, including labels and personalized packaging.

Over the years, Jenny & Co has established a strong production chain that combines factory-owned parts with those from trusted external partners.

Sustainability and ethics

Caring for the environment and people, collaboration, transparency and passion for work are the values of Jenny & Co. Jenny & Co attaches great importance to the selection of suppliers and raw materials. Every production is a joint participation and challenge, striving for a win-win situation.

Partner of Jenny & Co

Jenny & Co only collaborates with artisans from small family businesses that share their values and produce in an ethical and sustainable manner.

The mission of Jenny & Co

Jenny & Co aims to collaborate with brands of all sizes and seek a “Made in Italy” leather bag manufacturer that can offer high-quality materials at competitive prices.

Customize handbags with leather bag manufacturers

Florence Leather Factory is a leading enterprise in the production of men’s and women’s leather bags. The company was founded in the early 1980s by two Florentine artisans. They gradually began to produce prototypes of textile bags and won the favor of customers in Italy and even Europe.

For many years, the Florence Leather Goods Factory has been dedicated to manufacturing leather bags with Italian designs and researching high-quality leather. Italy is recognized worldwide as the leader in the artistic tanning industry.

To this day, the Florence Leather Goods Factory still employs a carefully selected network of artisan companies to enhance the Italian manufacturing style, with materials and production all carried out in Florence.

The main markets of the Florence Leather Goods Factory are Europe, the United States and Japan. Our clients include chain stores, importers, wholesalers and department stores.

Since the early 1980s, the Florence Leather Goods Factory has been manufacturing handbags, pouches, suitcases and belts.

The Florence Leather Goods Factory is located in the heart of Tuscany. All their bags are produced in Florence, which is the center of Italian leather goods. They are crafted by skilled artisans and can meet your personalized needs.

The Florence Leather Goods Factory uses only top-quality materials that have been certified by European regulations. Its products are exported to Europe and America, and its customers include wholesalers, chain stores and department stores.

Florenceleather is a company based in Florence that specializes in manufacturing leather bags and small leather goods for third parties. All leather products are made of high-quality Italian leather and are purely Italian manufactured.

Florenceleather adheres to the ancient tradition of Florentine artisans, creating high-quality products and providing customers with professional services throughout the entire process from design, prototyping to final products, along with rich experience.

Florenceleather follows the entire production process; From the initial stage of model design, the creation and die-cutting of paper models, all the way to the production and delivery of finished products.

Handmade

Their products are handcrafted by highly skilled Italian artisans.

“Made in Italy”

All the materials they use are from Italy, featuring high-quality raw materials, attention to detail and exquisite craftsmanship.

Customizable

They offer a variety of models and colors, providing full customization services based on specific customer requirements. With excellent cost performance and a production network, they can meet the needs of individual stores, boutiques, and brands of all sizes.

High quality

They design high-quality products, offering top-notch items handcrafted by skilled artisans, and provide customers with high-quality bags with enthusiasm and professionalism.

Niccolibags has been deeply rooted in tradition and experience, and has been in continuous operation since 1972, leaving a significant mark in the history of the leather goods industry. Niccolibags was founded and driven by the passion of the family. With their dedicated spirit and high-quality products, they have become a benchmark in the market.

Since 1972, Niccolibags has always adhered to exquisite craftsmanship in manufacturing leather products.

Exquisite craftsmanship

The team of niccolibags is composed of highly skilled artisans with rich experience, capable of making various types of bags. From design to finished product, every detail has been carefully considered.

The collision of technology and tradition

niccolibags employs advanced tools, such as the Mozart application for vector modeling and the Zund LC2400 electronic cutting table, enabling them to achieve precise and high-quality results even for large-scale productions.

From leather to the final product

Niccolibags’ factory meticulously manages every stage of production: from the selection and quality control of leather to cutting, preparation, assembly, finishing, packaging and final transportation.

Cooperation and quality control

The internal assembly and finishing are all carried out by niccolibags’ professional team, while the exterior is handled by a team they have carefully selected. They will strictly adhere to quality control standards at every stage.

Loipell was founded in 1993 as a small handicraft workshop. It has always adhered to the quality and tradition of Italian manufacturing. Over time, it has become one of the most important and well-known companies in the Florence area. Nowadays, they adhere to traditional craftsmanship, perfectly integrating modern technology with outstanding quality. With the ability to independently manage the entire production process, they have collaborated with many well-known luxury brands to ensure that their products always maintain high quality standards.

Morality, ecological sustainability and professional expertise form the values that guide Loipell’s work. The company places the value of people and respect for customers at the core of its mission, aiming to provide effective reference points for companies in the fashion industry.

Loipell is capable of independently completing the entire production process. Its exquisite technology and craftsmanship enable it to manage a large amount of work with ease.

This cycle concludes with meticulous quality control of the product.

Since 1980, Loipell has been adhering to the tradition of Florentine leather goods and handcrafting bags.

Florence Leather is a manufacturer specializing in high-end leather products and fashion accessories. Its headquarters is located in Florence, Italy, a city renowned for its long-standing tradition of leather craftsmanship. Since its establishment, the company has always adhered to the principle of “100% Made in Italy”. From raw material procurement to the final product, every link is completed in Italy to ensure that the product quality meets the most stringent industry standards.

Florence Leather selects the highest quality leather materials on the market, including top-grade vegetable-tanned cowhide, soft lambskin and specially treated waterproof leather. Meanwhile, the company is constantly exploring innovative materials, such as eco-friendly recycled leather and lightweight composite materials, to meet modern consumers’ demands for sustainable fashion.

All products are made by combining traditional Italian craftsmanship with advanced manufacturing techniques, ensuring that each individual item is durable, comfortable and features exquisite details.

As a trend-following manufacturer, the design team of Florence Leather pays close attention to global fashion trends and regularly launches product series that conform to current aesthetics. The brand style is mainly characterized by simplicity and elegance, while integrating modern elements, making its products suitable not only for daily wear but also for high-end business occasions.

Whether it is the classic tote bag, the exquisite clutch bag, or the fashionable belt and wallet, the products of Florence Leather all demonstrate outstanding design sense and practicality.

Florence Leather adopts a flexible business strategy, providing both White Label products for direct distribution to customers and Private Label customization services. White-label products can be dispatched immediately and are suitable for quick replenishment by wholesalers, buyer stores and e-commerce platforms.

Private label services, on the other hand, allow customers to customize exclusive products based on their own needs, including adjusting materials, colors, hardware accessories, etc., but the minimum order quantity (MOQ) must be met.

The success of Florence Leather stems not only from its outstanding product quality, but also from the extreme pursuit of details and the customer-oriented service concept. Whether you are a wholesaler, a retailer, or a brand seeking customized cooperation, you can find high-quality leather solutions that meet your needs here.

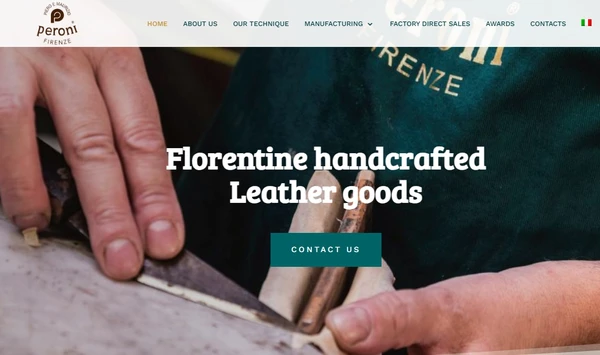

The origin of the Fratelli Peroni handicraft factory can be traced back to 1956, when the Peroni brothers Piero and Roberto established their fur and leather goods workshop in Florence.

Today, Maurizio and Marco, the third-generation successors of Peroni, have carried on the tradition of high-quality leather craftsmanship, retaining their professionalism and manual skills while adding creativity and an innovative spirit.

Peroni Firenze is a genuine Florentine handicraft company. Even the boss participates in production and trains employees every day.

These products emotionally enrich their owners: visually and tactilically, they immediately showcase the craftsmanship passed down from father to son, and are entirely crafted in accordance with the great tradition of “Florentine art leather” that can be traced back to the Renaissance.

The main source of inspiration is Florence’s artistic heritage, especially certain details in the museum collections. Ancient models are reinterpreted from a modern perspective, thus ensuring a perfect combination of the functionality and aesthetics of the items.

It also actively participates in the international fairs “Pitti Uomo” in Florence and “Mipel” in Milan.

For more than 65 years, Peroni has been making leather using the “cuoietto artistico Fiorentino” technique. This ancient craft originated in Florence during the Renaissance and has been passed down from generation to generation to the present day.

This unique Florentine craft requires no stitching when making leather goods. Every step is handcrafted by Peroni’s artisans, respecting craftsmanship and tradition.

First, select and cut the leather; Only by using plant tanning can the final effect be achieved, because the leather must remain in its natural state as much as possible before it can be shaped.

After the cutting is completed, wet the leather and fix it on a wooden mold to maintain its shape. After drying, the leather actually retains the shape printed on the wooden mold.

All the shaped leather fragments are then bonded together to finally complete the work.

After obtaining the required finished products, they enter the coloring stage. Start with the natural color of the leather and add color layer by layer until the desired tone is achieved.

The final step is to polish with natural wax to make the entire work dazzling and unique.

This technique is extremely time-consuming and requires great enthusiasm and skills from the artisans.

For instance, the production process of Peroni’s signature Tacco coin box involves no less than 37 steps. In their workshop, every piece of work is still handcrafted, with every detail meticulously crafted, from color to polishing, and even the 22K gold decoration, all completed by hand with bronze punches and rims.

Each of their products is accompanied by two certificates to prove its quality and origin.

Effebi, located in Scandicci, Florence, is a top leather goods manufacturing enterprise steered by the Lotti family, perfectly embodying the perfect integration of Italian traditional craftsmanship and modern industrialization. This modern production base not only embodies the passion for bag-making of three generations of the family, but also has become a core supplier for many international luxury brands with its ultimate pursuit of quality.

Effebi is a model in the luxury leather goods industry that combines passion, exquisite craftsmanship, family management and industrialization to create a powerful enterprise. With an unwavering pursuit of quality and a focus on details, Effebi has become a trusted partner for many well-known brands and carries forward the essence of Italian leather art.

The success of Effebi stems from its unique “industrialization of craftsmanship” model:

Complete industrial chain: Full-process autonomous control from design and research and development to finished product delivery.

Craftsmanship inheritance: Systematically integrating a century of leather goods making experience into the modern production system.

Talent cultivation: The average working experience of the professional technician team exceeds 15 years.

Effebi innovatively established the “exclusive studio” service model

Confidential Design Studio: Equipped with an independent sample-making team

Exclusive production line: Ensuring product uniqueness

Digital transparency: Customers can track production progress in real time

Effebi not only continues the leather goods manufacturing tradition of Florence, but also redefines the contemporary connotation of “Made in Italy” through continuous innovation, making it an important bridge connecting traditional craftsmanship and future fashion.

As a cutting-edge leather goods manufacturing group rooted in Florence, GAS, with its profound understanding of the essence of “Made in Italy”, is setting a new benchmark for the perfect balance of cost performance and quality in the global market. This young enterprise, with over 20 years of industry experience, ingeniously combines Tuscan traditional craftsmanship with modern production efficiency, becoming an important bridge connecting Italy’s exquisite handicrafts with international market demands.

Pure Italian genes: All products are strictly produced locally in Florence. From leather cutting to finished product assembly, the entire process adheres to the century-old tradition of Tuscany leather goods making, ensuring that each product carries the pure “Made in Italy” bloodline.

Trend insight ability: Establish a professional fashion analysis team, accurately grasp the popular trends in various regional markets around the world through exclusive information channels, organically combine cutting-edge design with classic craftsmanship, and create products that not only conform to current aesthetics but also stand the test of time.

Flexible production system: A complete supply chain network has been established, covering raw material procurement to manufacturing. It can flexibly adjust product parameters according to customer needs, supporting various demands from standard models to fully customized ones. The minimum order quantity threshold is highly competitive.

Quality and value balance: By optimizing the production process, while maintaining the standard of pure handcrafting, costs are controlled, enabling more consumers to enjoy the quality and design of top-quality Italian leather goods at reasonable prices.

Provide comprehensive private label (OEM/ODM) services

Support personalized customization: including adjustments to all elements such as pattern, leather material, and hardware accessories

A strict supplier screening system ensures the quality of raw materials

Precise market demand analysis and product planning support

Pierotucci was founded in 1972 on the picturesque Via Tuscanella in the heart of Florence.

Pierotucci is headquartered in Banio Alipoli, just a few minutes’ drive from the center of Florence. The exhibition hall enjoys a prime location, adjacent to the factory, covering an area of 600 square meters. It is filled with leather products handcrafted by their workshop, including bags, jackets, hats, gloves and small leather accessories, and even the collars of their furry pets.

Pierotucci’s mission is to produce high-quality leather bags and wallets, gloves, belts and other small leather goods. Their unique and elegant works have become mainstream in boutiques across Italy, serving local consumers and tourists.

Full industrial chain control – Independently complete the entire process from design, pattern making to finished products

Material selection – Only top-quality Italian vegetable-tanned leather and natural materials are used

Craftsmanship spirit – Each product needs to go through more than 20 manual procedures

Cultural Inheritance – Infusing the aesthetic code of Florence into modern design

Today, this brand that adheres to the principle of “100% Made in Florence “has become a bridge of craftsmanship that connects the traditional and contemporary lifestyles of Tuscany. Its products are not only practical accessories but also artworks that can be passed down, perfectly interpreting the slow fashion concept of “purchase is investment”.

Florence, as a world-class luxury leather goods manufacturing center, has given birth to many well-known luxury brands. Local manufacturers insist on 100% Italian manufacturing and are renowned for traditional techniques such as saddle stitching, but they face challenges such as high labor costs and limited production capacity.

If you are looking for a luxury leather bag manufacturer in Florence but are worried about the high cost, you might as well try to cooperate with a leather bag manufacturer in China. This can reduce the cost of your bags while also allowing you to quickly test the market.

Customize handbags in collaboration with world-class handbag manufacturers.

material Genuine Leather Closure Type Open Lining suede…

Mobile Website

Inquires Whatsapp