- +86 (0) 20-86655668

- info@gionar.com

English

English

July 28 , 2025

Sewing is a technology closely related to the fashion industry, including machine sewing techniques and hand sewing techniques. Sewing technology, when applied to clothing, bags, shoes, accessories or soft products, is the combined effect of their fabrics, stitches, yarns and post-treatment processes.

The application of sewing techniques in bags is also very important. Whether it is sewing a durable handbag with a machine or sewing some delicate details by hand, using the correct stitch is crucial for creating a strong and beautiful bag.

This article will explore the sewing techniques of bags making. Understanding different types of stitches is not only a matter of craftsmanship but also a key to ensuring the durability, performance and brand quality of the products.

Unlike clothing, bags are subjected to concentrated stress at the handles, seams, zippers and structural reinforcements. Incorrect pins may lead to premature wear, structural damage, or the product failing to meet consumers’ expectations. Whether you are creating a sturdy and durable tactical backpack or an exquisite leather handbag, the stitching will also affect the appearance and texture of the final product.

By mastering both Hand-Sewing and machine sewing, manufacturers can select the best approach to achieve the durability and brand appeal of their products.

Before sewing machines became daily necessities in households and factories, clothing, bags and the like were all made entirely by hand. This covers every step of the sewing process, such as sewing the edges, sewing two pieces of fabric, completing the seams, and so on. Nowadays, many products such as clothing and bags are still sewn by hand using basic sewing techniques. These needlework techniques are particularly useful in the fine detail areas of early prototype designs or custom bags or luxury bags.

Note: Modern factories use machines, but hand sewing remains very important. Because hand sewing is a perfect connection for hardware and adds decorative touch, especially when many machines cannot handle it.

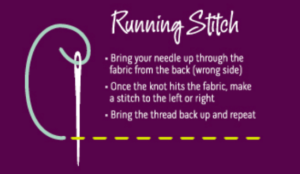

Simple and fast! Perfect for temporary stitching or gathering fabric.

The running stitch stands as the most fundamental and widely utilized one, where the needle and thread just alternate between going over and under two fabric pieces. It’s akin to a basting stitch, but it’s stitched more tightly to form a firm and lasting bond. This technique can be recognized by the gaps remaining between each stitch on both fabric surfaces, resulting in a dotted thread line. Employ it to swiftly assess form designs or create prototype samples.

The running stitch is one of the simplest and most basic stitches. It involves passing the needle in and out of the fabric at regular intervals, creating a series of evenly – spaced dashes on the surface of the fabric.

Usage in bag – making:

The back stitch is a variation of the running stitch, but after each needle pass, both the needle and the thread will double back on itself. This eliminates the visible gaps and dashed line effects in running stitches and forms smoother straight lines on the fabric surface. It is highly suitable for high-strength seams in small-scale production or custom bag design.

The backstitch is a strong and durable stitch that is often used for seams that need to withstand a lot of stress. It creates a continuous line of stitches that are reinforced by overlapping each stitch.

Usage in bag – making:

It is ideal for sewing the main seams of a bag, such as the seams that connect the sides of the bag body or the seams that attach the straps to the bag. These areas are subject to frequent pulling and stretching, and the backstitch provides the necessary strength.

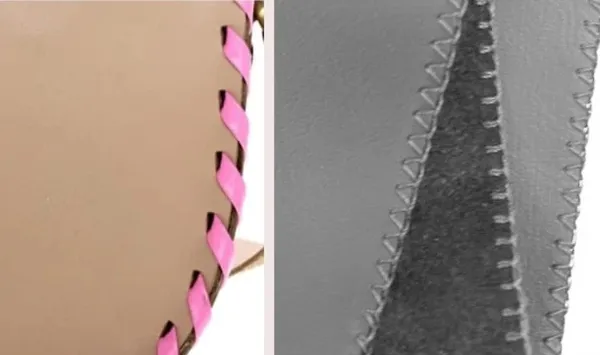

Whip stitch is a simple diagonal sewing technique, usually used to join two pieces of leather to form a firm and neat seam. It’s super fast and super simple! This simple needling technique has many variations and is widely used! From hemming, seaming, it is used in various processes, including sewing, knitting/crochet, and leather goods!

To achieve uniform and consistent stitches, the entry and exit points of the needle are of vital importance. Marking the stitch points with a line gauge or chalk or a detachable marking tool helps ensure that the distance and length of all stitches are equal, thus creating a more professional leather product.

The tension of the thread is an important factor in this needling technique – if the thread is too tight, it will cause gathers or puckering, while if it is too loose, it will be less secure and is prone to getting dirty.

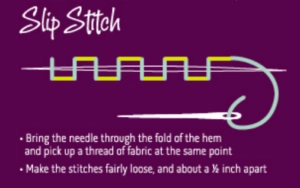

The slip stitch offers a durable and nearly invisible finish for garments, making it perfect for securing hemlines discreetly. Unlike the catch stitch, it creates seamless bonds on both fabric sides, leaving no visible traces. This stitch is ideal for attaching brand labels or decorative patches while maintaining a clean, professional appearance.

The slip stitch is a nearly invisible stitch that is used to join two pieces of fabric together while minimizing the visibility of the stitches on the right side of the fabric.

Usage in bag – making:

It is commonly used for closing the lining of a bag after it has been turned right – side out. It can also be used to attach a lining to the inside of a bag in a way that the stitches are not visible from the outside.

Saddle stitching stands as a cornerstone technique in leatherworking, essential for crafting everything from durable saddles and bridles to fine handbags, wallets and belts. This time-honored hand-sewing method produces exceptionally strong and long-lasting seams that outperform machine stitching in quality and resilience.

What makes saddle stitching superior? The technique employs two needles working in unison to create interlocking stitches within the leather. Unlike machine stitching that relies on a single continuous thread, each saddle stitch remains independent. This means if one stitch fails, the others maintain their integrity – a crucial advantage for premium leather goods requiring lifelong durability.

The benefits are clear: unparalleled safety, exceptional strength, and remarkable longevity. Each hand-pulled stitch creates a more secure bond than its machine-made counterpart, virtually eliminating the risk of unraveling. For artisans committed to quality, saddle stitching remains the gold standard, combining traditional craftsmanship with practical functionality for heirloom-worthy leather pieces.

| Stitch | Description | Why It’s Used for Bags | Best For |

| Running Stitch | The most basic hand stitch, where the needle is passed in and out of the fabric. | Good for temporarily holding pieces together (basting) before machine sewing, or for creating a decorative, rustic look. It is not strong enough for construction seams. | – Basting layers together.- Creating decorative, visible stitching (like in Sashiko). |

| Back stitch | The strongest hand stitch, it creates a solid line of stitching that resembles a machine stitch. | This is your go-to for any hand-sewn seam that needs to be strong and durable, such as repairing a seam or attaching a handle. | – Hand-sewing strong structural seams.- Attaching handles or D-rings.- Closing up small openings. |

| Whip stitch | A simple stitch that wraps around the edge of the fabric. | Useful for closing the final opening in a bag lining or for appliquéing patches onto a bag. It’s quick and relatively strong for finishing edges. | – Closing the turning gap in a lining.- Attaching patches or appliqué. |

| Ladder Stitch (Slip Stitch) | An invisible stitch used to join two folded edges of fabric. | Perfect for closing the final seam on a lined bag from the outside, creating a clean, invisible finish that looks professionally made. | – Invisibly closing the final seam in a lining.- Attaching a lining to a zipper. |

| Saddle Stitch | A traditional leatherworking stitch using two needles on a single thread, creating a very strong, interlocking stitch. | This is the strongest and most durable hand stitch, ideal for working with leather or other thick, non-fraying materials. | – Constructing leather bags by hand.- Attaching leather handles or details. |

The sewing machine’s stitches technique is characterized by high efficiency, precision and diversity, and is suitable for the production of bags with different material and process requirements. Compared with hand sewing, machine sewing is faster, less costly, and has uniform stitches, making it suitable for large-scale production. The standardized characteristics of machine sewing make it an indispensable technical support for the modern bag manufacturing industry.

There are various types of sewing machine stitches, each with its own characteristics and uses. Choosing the appropriate sewing stitches not only improves the quality of the finished product but also extends its service life. The key to making bags lies in flexibly choosing the fabric based on its thickness, application and force conditions.

The straight stitch, or lockstitch, serves as the fundamental stitching technique for bag construction, ideal for creating basic seams, precise topstitching, and structural reinforcement. Its strength ranges from medium to high, primarily determined by the thread thickness and tension settings. This versatile stitch works exceptionally well for lightweight to medium-weight bags such as totes and backpacks, where balanced durability and clean aesthetics are required.

The lockstitch’s simple yet effective interlocking mechanism ensures secure seams while maintaining a professional finish, making it the go-to choice for both functional and decorative stitching in bag manufacturing.

The back stitch is a fundamental yet highly versatile machine stitch technique widely used in bag manufacturing for its exceptional strength and durability. Unlike a standard straight stitch, this method creates overlapping stitches that reinforce seams at stress points where bags endure the most wear, such as handle attachments, strap connections, and structural joints.

During production, industrial sewing machines perform back stitching by reversing direction at each stitch endpoint, effectively doubling the thread density in critical areas. This technique significantly reduces the risk of seam failure compared to single-line straight stitches. Many manufacturers use back stitching in combination with bar tacks at anchor points for maximum reinforcement in backpacks, duffels, and heavy-duty totes.

Topstitching is a critical decorative and functional machine stitch technique that enhances both the aesthetics and durability of bags. This visible stitching runs parallel to seams or edges, serving multiple purposes: reinforcing structural integrity, creating clean finished edges, and adding professional detailing.

In production, industrial machines execute topstitching with heavier gauge threads (typically #40 or #69) at longer stitch lengths (3.5-4.5mm) for pronounced visual impact. The technique is particularly valuable for:

Premium bag manufacturers often combine topstitching with edge painting or piping for luxury finishes. Double-needle machines create parallel stitch lines for signature designer looks on backpacks, briefcases, and handbags.

While primarily decorative, proper topstitching significantly improves:

The box stitch (also called X-stitch or bartack) is a heavy-duty reinforcement technique essential for high-stress areas in bag construction. This industrial-grade stitch pattern forms a dense rectangular or X-shaped cluster of closely spaced stitches, creating maximum load-bearing capacity at critical connection points.

Key applications:

The zigzag stitch serves as a versatile solution for both functional and decorative applications in bag manufacturing. This distinctive back-and-forth stitch pattern offers unique advantages that straight stitches cannot provide, particularly when working with stretch fabrics or requiring seam flexibility.

Industry-specific implementations:

The triple straight stitch represents the gold standard for maximum seam security in heavy-duty bag construction. This advanced stitch formation creates three parallel rows of straight stitches in a single pass, delivering unparalleled strength for critical load-bearing applications.

| Stitch | Description | Why It’s Used for Bags | Best For |

| Straight Stitch | The most basic and common stitch, forming a single, straight line. | Forms the primary construction seams of the bag. A slightly longer stitch length (2.5-3.5 mm) is often recommended for bags, as it creates a stronger seam in thicker fabrics and looks more professional. | – Seaming main body panels.- Attaching pockets.- Creating topstitching. |

| Back Stitch | Stitching backward over the last few stitches at the beginning and end of a seam. | This “locks” the stitches in place, preventing them from unraveling under the stress and weight a bag endures. It is absolutely essential for durable construction. | – Securing the start and end of every seam. |

| Topstitch | A straight stitch sewn on the exterior of the bag, close to a seam or edge. | Adds a professional, crisp finish. It also helps seams lie flat and adds an extra layer of strength, particularly around the top opening and straps. | – Finishing the top edge of the bag.- Outlining pockets.- Reinforcing straps and handles. |

| Box Stitch | A square or rectangular stitch pattern, often with an ‘X’ stitched inside for added strength. | Provides powerful reinforcement to areas that bear a lot of weight and stress, preventing straps from tearing away from the bag body. | – Securely attaching handles and straps to the bag. |

| Zigzag Stitch | A stitch that goes from side to side in a zigzag pattern. | Primarily used to finish raw fabric edges to prevent them from fraying. This is crucial for unlined bags or for keeping the inside of a lined bag tidy and durable. | – Finishing raw seam allowances inside the bag. |

| Triple Straight Stitch | The machine stitches forward, backward, and then forward again for each stitch. | Creates a very thick, bold, and extremely strong stitch line. It’s excellent for a decorative topstitch that also provides superior strength. | – Decorative and functional topstitching.- Reinforcing seams on heavy-duty bags. |

| Feature | Machine Stitch | Hand Stitch (Saddle Stitch) |

| Speed | Fast (mass production) | Slow (artisanal) |

| Durability | Good (depends on stitch type) | Excellent (self-locking) |

| Appearance | Consistent, industrial | Handcrafted, premium |

| Best Use | Everyday bags, high-volume production | Luxury bags, repairs, bespoke work |

Machine stitching ensures efficiency, while hand stitching (like saddle stitch) offers superior longevity. Many high-end bags combine both—machine stitching for structure and hand finishing for premium touches.

| Brands | Stitches | Bag Styles |

|

Hermès |

Back Stitch, Ladder Stitch (Slip Stitch) | Kelly Bag

Crocodile Birkin |

|

Chanel |

Running Stitch, Back Stitch | Classic Flap

Boy Chanel |

|

Gucci |

Herringbone Stitch, Ladder Stitch (Slip Stitch) | Jackie 1961

Gucci Horsebit |

|

Song |

Running stitch, Herringbone Stitch | Amazing Song |

|

ZARA |

Running stitch, Overlock Stitch | ZARA Basic Tote Bag |

Hand stitching and machine stitching represent two distinct approaches in leathercraft, each with unique advantages and applications. Hand stitching is ideal for high-end leather goods, repairs, and bespoke pieces where precision and longevity are paramount. Machine stitching excels in speed, consistency, and efficiency, making it indispensable for mass production.

The synergy between both methods is increasingly common in modern leatherworking. Many luxury brands combine machine stitching for structural seams with hand finishing for visible details, blending efficiency with craftsmanship. Ultimately, the choice between hand and machine stitching depends on the project’s demands—balancing time, cost, and durability—but their collaboration elevates the craft to new heights.

material Genuine Leather Closure Type Open Lining suede…

Mobile Website

Inquires Whatsapp